Long welding neck flanges (“LWN”) are similar to weld neck flanges, with the exception that the neck (tapered hub) is extended and acts as a boring extension.

Rio Engineering takes this opportunity to introduces itself as one of the leading Manufacturer, Exporters & Stockiest of flanges and pipe fittings. We are an ISO 9001:2000 Certified company accredited by QA International Certification ( UKAS – LONDON ).

We Rio Engineering are provided specialized and standard connection types and components for many different applications so you can find the long welding neck flange fittings that work. Our Experts Team of Professional in Rio Engineering from Mumbai, Maharashtra, India ensures that each and every product of Long Welding Neck Flanges meets the international Manufacturing standards for flange shape, weight, size, and material as set by International Standers.

Owing to our rich industrial experience, we are offering a comprehensive range of Long Weld Neck Flanges. The professionals of our organization source these neck flanges from trusted vendors. These flanges are unique due to their simple connectivity with other pipes. Moreover, our products are extensively used in refining industries for linking purposes. Our esteemed patrons can avail of this qualitative range of flanges at industry-leading prices.

| Specification | Stainless Steel |

| Flanges Material Grades: | ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F310MoLN, F316, F316H, F316N, F316LN, F316Ti, F317, F317L, F321, F321H, F347, F347H, F348, F348H, F904L. |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Duplex & Super Duplex steel |

| Flanges Material Grades: | Duplex Flange ASTM A182 UNS S31803 UNS S32205 & Super Duplex ASTM A182 UNS S32750 – 32760 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Nickel Alloy Steel |

| Flanges Material Grades: | ASTM B160 Nickel 200 & 201 , ASTM B166 Inconel 600, ASTM B564 Inconel 625, STM B425 Incoloy 800, ASTM B564 Incoloy 825, ASTM B564 Monel K400 & K500, ASTM B564 Hastelloy C276, B2, D205 & G30. |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Carbon Steel |

| Flanges Material Grades: | ASTM A105, ASTM A350 LF1, LF2, LF3, ASTM A694 F42, F46, F48, F50, F52, f56, F60, F65, F70 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Alloy Steel |

| Flanges Material Grades: | ASTM A182 F1, F2, F5, F5a, F9, F11, F22 and F91 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

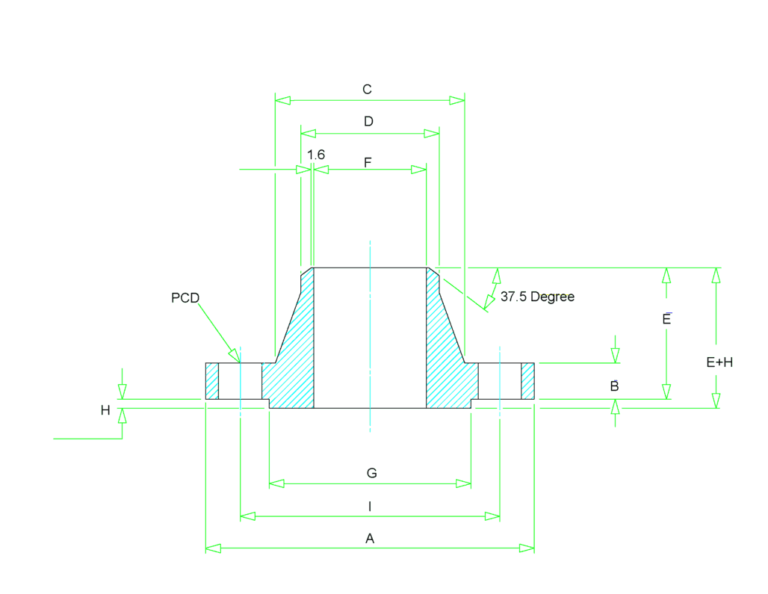

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Refer Note | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 95 | 12.7 | 38 | 21.3 | 51 | Refer Note | 34.9 | 2 | 66.7 | 1.6 |

| 3/4 | 20 | 115 | 14.3 | 48 | 26.7 | 56 | 42.9 | 2 | 82.6 | 1.6 | |

| 1 | 25 | 125 | 15.9 | 54 | 33.4 | 60 | 50.8 | 2 | 88.9 | 1.6 | |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 42.2 | 64 | 63.5 | 2 | 98.4 | 1.6 | |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 48.3 | 67 | 73 | 2 | 114.3 | 1.6 | |

| 2 | 50 | 165 | 20.7 | 84 | 60.3 | 68 | 92.1 | 2 | 127 | 1.6 | |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 73 | 75 | 104.8 | 2 | 149.2 | 1.6 | |

| 3 | 80 | 210 | 27 | 117 | 88.9 | 78 | 127 | 2 | 168.3 | 1.6 | |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 101.6 | 79 | 139.7 | 2 | 184.2 | 1.6 | |

| 4 | 100 | 255 | 30.2 | 146 | 114.3 | 84 | 157.2 | 2 | 200 | 1.6 | |

| 5 | 125 | 280 | 33.4 | 178 | 141.3 | 97 | 185.7 | 2 | 235 | 1.6 | |

| 6 | 150 | 320 | 35 | 206 | 168.3 | 97 | 215.9 | 2 | 269.9 | 1.6 | |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 1.6 | |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.4 | 1.6 | |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 1.6 | |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 1.6 | |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 1.6 | |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 533.4 | 2 | 628.6 | 1.6 | |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 1.6 | |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 95 | 14.3 | 38 | 21.3 | 52 | Refer Note | 34.9 | 7 | 66.7 | 1.6 |

| 3/4 | 20 | 115 | 15.9 | 48 | 26.7 | 57 | 42.9 | 7 | 82.6 | 1.6 | |

| 1 | 25 | 125 | 17.5 | 54 | 33.4 | 62 | 50.8 | 7 | 88.9 | 1.6 | |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 42.2 | 67 | 63.5 | 7 | 98.4 | 1.6 | |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 48.3 | 70 | 73 | 7 | 114.3 | 1.6 | |

| 2 | 50 | 165 | 25.4 | 84 | 60.3 | 73 | 92.1 | 7 | 127 | 1.6 | |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 73 | 79 | 104.8 | 7 | 149.2 | 1.6 | |

| 3 | 80 | 210 | 31.8 | 117 | 88.9 | 83 | 127 | 7 | 168.3 | 1.6 | |

| 3 1/2 | 90 | 230 | 35 | 133 | 101.6 | 86 | 139.7 | 7 | 184.2 | 1.6 | |

| 4 | 100 | 255 | 35 | 146 | 114.3 | 89 | 157.2 | 7 | 200 | 1.6 | |

| 5 | 125 | 280 | 38.1 | 178 | 141.3 | 102 | 185.7 | 7 | 235 | 1.6 | |

| 6 | 150 | 320 | 41.3 | 206 | 168.3 | 103 | 215.9 | 7 | 269.9 | 1.6 | |

| 8 | 200 | 380 | 47.7 | 260 | 219.1 | 117 | 269.9 | 7 | 330 | 1.6 | |

| 10 | 250 | 445 | 54 | 321 | 273 | 124 | 323.8 | 7 | 387.4 | 1.6 | |

| 12 | 300 | 520 | 57.2 | 375 | 323.8 | 137 | 381 | 7 | 450.8 | 1.6 | |

| 14 | 350 | 585 | 60.4 | 425 | 355.6 | 149 | 412.8 | 7 | 514.4 | 1.6 | |

| 16 | 400 | 650 | 63.5 | 483 | 406.4 | 152 | 469.9 | 7 | 571.5 | 1.6 | |

| 18 | 450 | 710 | 66.7 | 533 | 457 | 165 | 533.4 | 7 | 628.6 | 1.6 | |

| 20 | 500 | 775 | 69.9 | 587 | 508 | 168 | 584.2 | 7 | 685.8 | 1.6 | |

| 24 | 600 | 915 | 76.2 | 702 | 610 | 175 | 692.2 | 7 | 812.8 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 95 | 14.3 | 38 | 21.3 | 52 | Refer Note | 34.9 | 7 | 66.7 | 1.6 |

| 3/4 | 20 | 115 | 15.9 | 48 | 26.7 | 57 | 42.9 | 7 | 82.6 | 1.6 | |

| 1 | 25 | 125 | 17.5 | 54 | 33.4 | 62 | 50.8 | 7 | 88.9 | 1.6 | |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 42.2 | 67 | 63.5 | 7 | 98.4 | 1.6 | |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 48.3 | 70 | 73 | 7 | 114.3 | 1.6 | |

| 2 | 50 | 165 | 25.4 | 84 | 60.3 | 73 | 92.1 | 7 | 127 | 1.6 | |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 73 | 79 | 104.8 | 7 | 149.2 | 1.6 | |

| 3 | 80 | 210 | 31.8 | 117 | 88.9 | 83 | 127 | 7 | 168.3 | 1.6 | |

| 3 1/2 | 90 | 230 | 35 | 133 | 101.6 | 86 | 139.7 | 7 | 184.2 | 1.6 | |

| 4 | 100 | 275 | 38.1 | 152 | 114.3 | 102 | 157.2 | 7 | 215.9 | 1.6 | |

| 5 | 125 | 330 | 44.5 | 189 | 141.3 | 114 | 185.7 | 7 | 266.7 | 1.6 | |

| 6 | 150 | 355 | 47.7 | 222 | 168.3 | 117 | 215.9 | 7 | 292.1 | 1.6 | |

| 8 | 200 | 420 | 55.6 | 273 | 219.1 | 133 | 269.9 | 7 | 349.2 | 1.6 | |

| 10 | 250 | 510 | 63.5 | 343 | 273 | 152 | 323.8 | 7 | 431.8 | 1.6 | |

| 12 | 300 | 560 | 66.7 | 400 | 323.8 | 156 | 381 | 7 | 489 | 1.6 | |

| 14 | 350 | 605 | 69.9 | 432 | 355.6 | 165 | 412.8 | 7 | 527 | 1.6 | |

| 16 | 400 | 685 | 76.2 | 495 | 406.4 | 178 | 469.9 | 7 | 603.2 | 1.6 | |

| 18 | 450 | 745 | 82.6 | 546 | 457 | 184 | 533.4 | 7 | 654 | 1.6 | |

| 20 | 500 | 815 | 88.9 | 610 | 508 | 190 | 584.2 | 7 | 723.9 | 1.6 | |

| 24 | 600 | 940 | 101.6 | 718 | 610 | 203 | 692.2 | 7 | 838.2 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 120 | 22.3 | 38 | 21.3 | 60 | Refer Note | 34.9 | 7 | 82.6 | 1.6 |

| 3/4 | 20 | 130 | 25.4 | 44 | 26.7 | 70 | 42.9 | 7 | 88.9 | 1.6 | |

| 1 | 25 | 150 | 28.6 | 52 | 33.4 | 73 | 50.8 | 7 | 101.6 | 1.6 | |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 42.2 | 73 | 63.5 | 7 | 111.1 | 1.6 | |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 48.3 | 83 | 73 | 7 | 123.8 | 1.6 | |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 1.6 | |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 1.6 | |

| 3 | 80 | 240 | 38.1 | 127 | 88.9 | 102 | 127 | 7 | 190.5 | 1.6 | |

| 4 | 100 | 290 | 44.5 | 159 | 114.3 | 114 | 157.2 | 7 | 235 | 1.6 | |

| 5 | 125 | 350 | 50.8 | 190 | 141.3 | 127 | 185.7 | 7 | 279.4 | 1.6 | |

| 6 | 150 | 380 | 55.6 | 235 | 168.3 | 140 | 215.9 | 7 | 317.5 | 1.6 | |

| 8 | 200 | 470 | 63.5 | 298 | 219.1 | 162 | 269.9 | 7 | 393.7 | 1.6 | |

| 10 | 250 | 545 | 69.9 | 368 | 273 | 184 | 323.8 | 7 | 469.9 | 1.6 | |

| 12 | 300 | 610 | 79.4 | 419 | 323.8 | 200 | 381 | 7 | 533.4 | 1.6 | |

| 14 | 350 | 640 | 85.8 | 451 | 355.6 | 213 | 412.8 | 7 | 558.8 | 1.6 | |

| 16 | 400 | 705 | 88.9 | 508 | 406.4 | 216 | 469.9 | 7 | 616 | 1.6 | |

| 18 | 450 | 785 | 101.6 | 565 | 457 | 229 | 533.4 | 7 | 685.8 | 1.6 | |

| 20 | 500 | 855 | 108 | 622 | 508 | 248 | 584.2 | 7 | 749.3 | 1.6 | |

| 24 | 600 | 1040 | 139.7 | 749 | 610 | 292 | 692.2 | 7 | 901.7 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 120 | 22.3 | 38 | 21.3 | 60 | Refer Note | 34.9 | 7 | 82.6 | 1.6 |

| 3/4 | 20 | 130 | 25.4 | 44 | 26.7 | 70 | 42.9 | 7 | 88.9 | 1.6 | |

| 1 | 25 | 150 | 28.6 | 52 | 33.4 | 73 | 50.8 | 7 | 101.6 | 1.6 | |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 42.2 | 73 | 63.5 | 7 | 111.1 | 1.6 | |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 48.3 | 83 | 73 | 7 | 123.8 | 1.6 | |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 1.6 | |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 1.6 | |

| 3 | 80 | 265 | 47.7 | 133 | 88.9 | 117 | 127 | 7 | 203.2 | 1.6 | |

| 4 | 100 | 310 | 54 | 162 | 114.3 | 124 | 157.2 | 7 | 241.3 | 1.6 | |

| 5 | 125 | 375 | 73.1 | 197 | 141.3 | 156 | 185.7 | 7 | 292.1 | 1.6 | |

| 6 | 150 | 395 | 82.6 | 229 | 168.3 | 171 | 215.9 | 7 | 317.5 | 1.6 | |

| 8 | 200 | 485 | 92.1 | 292 | 219.1 | 213 | 269.9 | 7 | 393.7 | 1.6 | |

| 10 | 250 | 585 | 108 | 368 | 273 | 254 | 323.8 | 7 | 482.6 | 1.6 | |

| 12 | 300 | 675 | 123.9 | 451 | 323.8 | 283 | 381 | 7 | 571.5 | 1.6 | |

| 14 | 350 | 750 | 133.4 | 495 | 355.6 | 298 | 412.8 | 7 | 635 | 1.6 | |

| 16 | 400 | 825 | 146.1 | 552 | 406.4 | 311 | 469.9 | 7 | 704.8 | 1.6 | |

| 18 | 450 | 915 | 162 | 597 | 457 | 327 | 533.4 | 7 | 774.7 | 1.6 | |

| 20 | 500 | 985 | 177.8 | 641 | 508 | 356 | 584.2 | 7 | 831.8 | 1.6 | |

| 24 | 600 | 1170 | 203.2 | 762 | 610 | 406 | 692.2 | 7 | 990.6 | 1.6 | |

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 135 | 30.2 | 43 | 21.3 | 73 | Refer Note | 34.9 | 7 | 88.9 | 1.6 |

| 3/4 | 20 | 140 | 31.8 | 51 | 26.7 | 79 | 42.9 | 7 | 95.2 | 1.6 | |

| 1 | 25 | 160 | 35 | 57 | 33.4 | 89 | 50.8 | 7 | 108 | 1.6 | |

| 1 1/4 | 32 | 185 | 38.1 | 73 | 42.2 | 95 | 63.5 | 7 | 130.2 | 1.6 | |

| 1 1/2 | 40 | 205 | 44.5 | 79 | 48.3 | 111 | 73 | 7 | 146 | 1.6 | |

| 2 | 50 | 235 | 50.9 | 95 | 60.3 | 127 | 92.1 | 7 | 171.4 | 1.6 | |

| 2 1/2 | 65 | 265 | 57.2 | 114 | 73 | 143 | 104.8 | 7 | 196.8 | 1.6 | |

| 3 | 80 | 305 | 66.7 | 133 | 88.9 | 168 | 127 | 7 | 228.6 | 1.6 | |

| 4 | 100 | 355 | 76.2 | 165 | 114.3 | 190 | 157.2 | 7 | 273 | 1.6 | |

| 5 | 125 | 420 | 92.1 | 203 | 141.3 | 229 | 185.7 | 7 | 323.8 | 1.6 | |

| 6 | 150 | 485 | 108 | 235 | 168.3 | 273 | 215.9 | 7 | 368.3 | 1.6 | |

| 8 | 200 | 550 | 127 | 305 | 219.1 | 318 | 269.9 | 7 | 438.2 | 1.6 | |

| 10 | 250 | 675 | 165.1 | 375 | 273 | 419 | 323.8 | 7 | 539.8 | 1.6 | |

| 12 | 300 | 760 | 184.2 | 441 | 323.8 | 464 | 381 | 7 | 619.1 | 1.6 | |