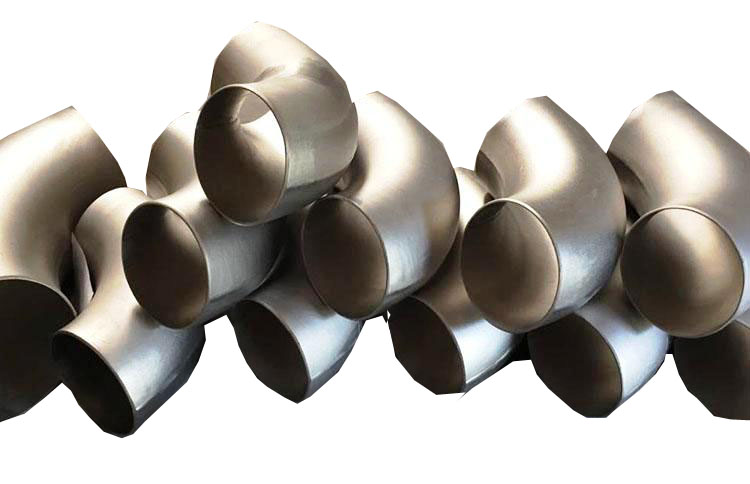

We Rio Engineering are leading manufacturers of flanges and Pipe Fittings from Mumbai, Maharashtra, India. We manufacturing BUTT WELD ELBOW 45/90/180 DEG as per International standard and material Grad.

ASME B16.9 butt-weld elbows are manufactured in a wide range of dimensions (combinations of outside diameter and wall thickness) to fit ASME B36.10 and ASME B36.19 carbon, alloy, and stainless steel pipes of any size between 2 and 48 inches (and above). Butt-weld elbows below 24 inches in diameter are produced by cutting, heating, and bending seamless steel pipes; pipe elbows of larger sizes are manufactured, instead, from welded pipes or steel plates. The three most common types of elbows in piping are the 45, 90, and 180 degrees (or return elbow) some special types of pipe elbows are:

Size: 1/2″NB TO 48″

Schedule: SCH20 ,SCH30,SCH40, STD, SCH80,XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

TYPE: SEAMLESS / ERW / Welded / Fabricated

MATERIALS:

Size: 1/2″NB TO 48″

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS TYPE: SEAMLESS / ERW / Welded / Fabricated

MATERIALS:

• Stainless Steel –

ASTMA403 W2P GR.304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

• Carbon Steel –

ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH60, WPHY 65, WPHY 70.

• Low-Temperature Carbon Steel –

ASTM A 234 WPL3 / A420WPL6

• Alloy Steel :

ASTM/ ASME A/SA 234 GR.WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

• Duplex steel :

ASTM A 815, UNSNO 31803, S 32205.

Size: 1/2″NB TO 48″

Schedule: SCH20 , SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

TYPE: SEAMLESS / ERW / welded / Fabricated

MATERIALS:

• Stainless Steel 90″ elbow –

ASTMA403 W2P GR.304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

• Carbon Steel 90″ elbow –

ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH60, WPHY 65, WPHY 70.

• Low Temperature carbon steel 90″ elbow –

ASTM A 234 WPL3 / A420WPL6.

• Alloy steel 90″ elbow:

ASTM/ ASME A/SA 234 GR.WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

• Duplex steel elbow:

ASTM A 815, UNSNO 31803, S 32205.

VALUE ADDED SERVICE:

• Hot Dip Galvanizing

• Epoxy Coating

• Electro Polish

A pipe connector with an inlet and an outlet in two different bore sizes is used instead of the combination of a standard elbow and concentric reducer.

Large size elbow assembled by joining steel plates

The center to face distance of a long radius pipe elbow is always 1.5 times the nominal pipe size, whereas, for a short radius pipe elbow, the center to face distance is equal to the nominal pipe size.

Example: For a 4 inches long radius (LR) butt weld elbow, the center to face distance is 4 x 25.4 x 1.5 = 152.4 mm;

For a short radius butt weld elbow, the center to face distance is instead 4 x 25.4 x 1 = 101.6 mm. Short radius pipe elbows are available only for the 90 and 180-degree configuration (and not for the 45 degrees); instead, long radius elbows are available for all degrees.

PIPE ELBOW MANUFACTURING PROCESS:

Butt-weld elbows 45 and 90 degrees can be manufactured in different ways, the main ones are the “mandrel process” and the “cold forming” (other methods are the elliptical forming and the double-seam welding method).