We Rio Engineering are Manufacturers and Exporters of Blind Flanges as per International Standard from Mumbai, Maharashtra, INDIA.

Contrary to all the flange types seen above, blind flanges do not have a center hole, and are used to blind or seal a pipeline, a valve/pressure vessel and block the flow of the fluid. Blind flanges have to withstand remarkable mechanical stress due to the system pressure and the required bolting forces.

Blind flanges allow easy access to the pipeline, as blind flanges can be easily unbolted to let the operator execute activities inside the terminal end of the pipe (this is also the reason why the blind flange type is used as a manhole for pressure vessels, at times). It is maybe interesting to observe that, while this blind flanges type is easier to manufacture, blind flanges are sold at a premium average cost per kilogram compared to the other flange types.

Blind Flanges are manufactured without a bore and used to blank off the ends of piping, valves, and pressure vessel openings.

From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these blind flanges are suitable for higher pressure temperature applications.

| Specification | Stainless Steel Flanges |

| Flanges Material Grades: | ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F310MoLN, F316, F316H, F316N, F316LN, F316Ti, F317, F317L, F321, F321H, F347, F347H, F348, F348H, F904L. |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Duplex & Super Duplex steel |

| Flanges Material Grades: | Duplex Flange ASTM A182 UNS S31803 UNS S32205 & Super Duplex ASTM A182 UNS S32750 – 32760 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Nickel Alloy Steel |

| Flanges Material Grades: | ASTM B160 Nickel 200 & 201 , ASTM B166 Inconel 600, ASTM B564 Inconel 625, STM B425 Incoloy 800, ASTM B564 Incoloy 825, ASTM B564 Monel K400 & K500, ASTM B564 Hastelloy C276, B2, D205 & G30. |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Carbon Steel |

| Flanges Material Grades: | ASTM A105, ASTM A350 LF1, LF2, LF3, ASTM A694 F42, F46, F48, F50, F52, f56, F60, F65, F70 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Specification | Alloy Steel |

| Flanges Material Grades: | ASTM A182 F1, F2, F5, F5a, F9, F11, F22 and F91 |

| Flange Size | 1/2″ (15 NB) to 48” (1200NB) & above as per client requirement |

| Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Flange Pressure Rating DIN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Pressure Rating JIS | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Flange Pressure Rating EN | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Pressure Rating UNI | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar |

| Flange Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Most common types of Flanges | Forged / threaded / screwed / Plate |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

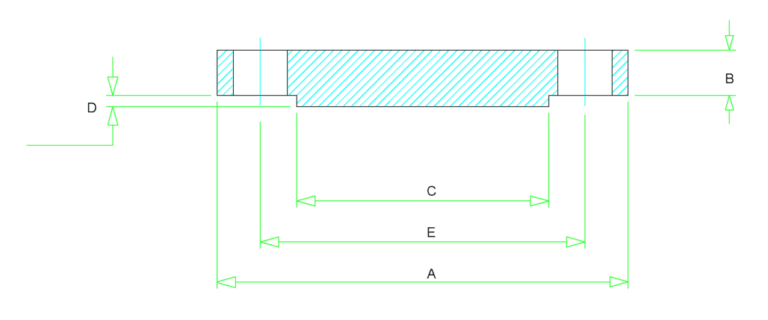

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 95 | 12.7 | 34.9 | 2 | 66.7 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.4 |

| 3/4 | 20 | 115 | 14.3 | 42.9 | 2 | 82.6 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 50.8 | 2 | 88.9 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 63.5 | 2 | 98.4 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 73 | 2 | 114.3 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 92.1 | 2 | 127 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 2 1/2 | 65 | 190 | 23.9 | 104.8 | 2 | 149.2 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 5.5 |

| 3 | 80 | 210 | 27 | 127 | 2 | 168.3 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 7.3 |

| 3 1/2 | 90 | 230 | 28.6 | 139.7 | 2 | 184.2 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 9.6 |

| 4 | 100 | 255 | 30.2 | 157.2 | 2 | 200 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 12.3 |

| 5 | 125 | 280 | 33.4 | 185.7 | 2 | 235 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 15.9 |

| 6 | 150 | 320 | 35 | 215.9 | 2 | 269.9 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 22.7 |

| 8 | 200 | 380 | 39.7 | 269.9 | 2 | 330.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 36 |

| 10 | 250 | 445 | 46.1 | 323.8 | 2 | 387.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 57 |

| 12 | 300 | 520 | 49.3 | 381 | 2 | 450.8 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 84 |

| 14 | 350 | 585 | 52.4 | 412.8 | 2 | 514.4 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 113 |

| 16 | 400 | 650 | 55.6 | 469.9 | 2 | 571.5 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 134 |

| 18 | 450 | 710 | 58.8 | 533.4 | 2 | 628.6 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 181 |

| 20 | 500 | 775 | 62 | 584.2 | 2 | 685.8 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 230 |

| 24 | 600 | 915 | 68.3 | 692.2 | 2 | 812.8 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 359 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 95 | 14.3 | 34.9 | 7 | 66.7 | 4 | 1/2 | 75 | 5/8 | M14 | 1.5 |

| 3/4 | 20 | 115 | 15.9 | 42.9 | 7 | 82.6 | 4 | 5/8 | 90 | 3/4 | M16 | 1.5 |

| 1 | 25 | 125 | 17.5 | 50.8 | 7 | 88.9 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 63.5 | 7 | 98.4 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 73 | 7 | 114.3 | 4 | 3/4 | 110 | 7/8 | M20 | 3.7 |

| 2 | 50 | 165 | 25.4 | 92.1 | 7 | 127 | 8 | 5/8 | 110 | 3/4 | M16 | 4.6 |

| 2 1/2 | 65 | 190 | 28.6 | 104.8 | 7 | 149.2 | 8 | 3/4 | 120 | 7/8 | M20 | 6.8 |

| 3 | 80 | 210 | 31.8 | 127 | 7 | 168.3 | 8 | 3/4 | 125 | 7/8 | M20 | 9.1 |

| 3 1/2 | 90 | 230 | 35 | N/A | 7 | 184.2 | 8 | 7/8 | 140 | 1 | M24 | 13.2 |

| 4 | 100 | 255 | 35 | 157.2 | 7 | 200 | 8 | 7/8 | 140 | 1 | M24 | 15 |

| 5 | 125 | 280 | 38.1 | 185.7 | 7 | 235 | 8 | 7/8 | 145 | 1 | M24 | 20 |

| 6 | 150 | 320 | 41.3 | 215.9 | 7 | 269.9 | 12 | 7/8 | 150 | 1 | M24 | 28 |

| 8 | 200 | 380 | 47.7 | 269.9 | 7 | 330 | 12 | 1 | 170 | 1 1/8 | M27 | 46 |

| 10 | 250 | 445 | 54 | 323.8 | 7 | 387.4 | 16 | 1 1/8 | 190 | 1 1/4 | M30 | 71 |

| 12 | 300 | 520 | 57.2 | 381 | 7 | 450.8 | 16 | 1 1/4 | 205 | 1 3/8 | M33 | 102 |

| 14 | 350 | 585 | 60.4 | 412.8 | 7 | 514.4 | 20 | 1 1/4 | 210 | 1 3/8 | M33 | 132 |

| 16 | 400 | 650 | 63.5 | 469.9 | 7 | 571.5 | 20 | 1 3/8 | 220 | 1 1/2 | M36 | 168 |

| 18 | 450 | 710 | 66.7 | 533.4 | 7 | 628.6 | 24 | 1 3/8 | 230 | 1 1/2 | M36 | 207 |

| 20 | 500 | 775 | 69.9 | 584.2 | 7 | 685.8 | 24 | 1 1/2 | 240 | 1 3/4 | M39 | 266 |

| 24 | 600 | 915 | 76.2 | 692.2 | 7 | 812.8 | 24 | 1 3/4 | 265 | 1 7/8 | M45 | 405 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 95 | 14.3 | 34.9 | 7 | 66.7 | 4 | 1/2 | 75 | 5/8 | M14 | 1.4 |

| 3/4 | 20 | 115 | 15.9 | 42.9 | 7 | 82.6 | 4 | 5/8 | 90 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 17.5 | 50.8 | 7 | 88.9 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 63.5 | 7 | 98.4 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 73 | 7 | 114.3 | 4 | 3/4 | 110 | 7/8 | M20 | 3.7 |

| 2 | 50 | 165 | 25.4 | 92.1 | 7 | 127 | 8 | 5/8 | 110 | 3/4 | M16 | 4.6 |

| 2 1/2 | 65 | 190 | 28.6 | 104.8 | 7 | 149.2 | 8 | 3/4 | 120 | 7/8 | M20 | 6.8 |

| 3 | 80 | 210 | 31.8 | 127 | 7 | 168.3 | 8 | 3/4 | 125 | 7/8 | M20 | 9.1 |

| 3 1/2 | 90 | 230 | 35 | N/A | 7 | 184.2 | 8 | 7/8 | 140 | 1 | M24 | 13.2 |

| 4 | 100 | 275 | 38.1 | 157.2 | 7 | 215.9 | 8 | 7/8 | 145 | 1 | M24 | 18.7 |

| 5 | 125 | 330 | 44.5 | 185.7 | 7 | 266.7 | 8 | 1 | 165 | 1 1/8 | M27 | 31 |

| 6 | 150 | 355 | 47.7 | 215.9 | 7 | 292.1 | 12 | 1 | 170 | 1 1/8 | M27 | 39 |

| 8 | 200 | 420 | 55.6 | 269.9 | 7 | 349.2 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 64 |

| 10 | 250 | 510 | 63.5 | 323.8 | 7 | 431.8 | 16 | 1 1/4 | 215 | 1 3/8 | M33 | 105 |

| 12 | 300 | 560 | 66.7 | 381 | 7 | 489 | 20 | 1 1/4 | 220 | 1 3/8 | M33 | 134 |

| 14 | 350 | 605 | 69.9 | 412.8 | 7 | 527 | 20 | 1 3/8 | 235 | 1 1/2 | M36 | 161 |

| 16 | 400 | 685 | 76.2 | 469.9 | 7 | 603.2 | 20 | 1 1/2 | 255 | 1 5/8 | M39 | 225 |

| 18 | 450 | 745 | 82.6 | 533.4 | 7 | 654 | 20 | 1 5/8 | 275 | 1 3/4 | M42 | 286 |

| 20 | 500 | 815 | 88.9 | 584.2 | 7 | 723.9 | 24 | 1 5/8 | 285 | 1 3/4 | M42 | 368 |

| 24 | 600 | 940 | 101.6 | 692.2 | 7 | 838.2 | 24 | 1 7/8 | 330 | 2 | M48 | 568 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 120 | 22.3 | 34.9 | 7 | 82.6 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 42.9 | 7 | 88.9 | 4 | 3/4 | 115 | 7/8 | M20 | 2.7 |

| 1 | 25 | 150 | 28.6 | 50.8 | 7 | 101.6 | 4 | 7/8 | 125 | 1 | M24 | 3.6 |

| 1 1/4 | 32 | 160 | 28.6 | 63.5 | 7 | 111.1 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 73 | 7 | 123.8 | 4 | 1 | 140 | 1 1/8 | M27 | 5.9 |

| 2 | 50 | 215 | 38.1 | 92.1 | 7 | 165.1 | 8 | 7/8 | 145 | 1 | M24 | 10.1 |

| 2 1/2 | 65 | 245 | 41.3 | 104.8 | 7 | 190.5 | 8 | 1 | 160 | 1 1/8 | M27 | 16 |

| 3 | 80 | 240 | 38.1 | 127 | 7 | 190.5 | 8 | 7/8 | 145 | 1 | M24 | 13 |

| 4 | 100 | 290 | 44.5 | 157.2 | 7 | 235 | 8 | 1 1/8 | 170 | 1 1/4 | M30 | 24.5 |

| 5 | 125 | 350 | 50.8 | 185.7 | 7 | 279.4 | 8 | 1 1/4 | 190 | 1 3/8 | M33 | 39.5 |

| 6 | 150 | 380 | 55.6 | 215.9 | 7 | 317.5 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 53 |

| 8 | 200 | 470 | 63.5 | 269.9 | 7 | 393.7 | 12 | 1 3/8 | 220 | 1 1/2 | M36 | 91 |

| 10 | 250 | 545 | 69.9 | 323.8 | 7 | 469.9 | 16 | 1 3/8 | 235 | 1 1/2 | M36 | 132 |

| 12 | 300 | 610 | 79.4 | 381 | 7 | 533.4 | 20 | 1 3/8 | 255 | 1 1/2 | M36 | 189 |

| 14 | 350 | 640 | 85.8 | 412.8 | 7 | 558.8 | 20 | 1 1/2 | 275 | 1 5/8 | M39 | 237 |

| 16 | 400 | 705 | 88.9 | 469.9 | 7 | 616 | 20 | 1 5/8 | 285 | 1 3/4 | M42 | 273 |

| 18 | 450 | 785 | 101.6 | 533.4 | 7 | 685.8 | 20 | 1 7/8 | 325 | 2 | M48 | 367 |

| 20 | 500 | 855 | 108 | 584.2 | 7 | 749.3 | 20 | 2 | 350 | 2 1/8 | M52 | 463 |

| 24 | 600 | 1040 | 139.7 | 692.2 | 7 | 901.7 | 20 | 2 1/2 | 440 | 2 5/8 | M64 | 875 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 120 | 22.3 | 34.9 | 7 | 82.6 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 42.9 | 7 | 88.9 | 4 | 3/4 | 115 | 7/8 | M20 | 2.7 |

| 1 | 25 | 150 | 28.6 | 50.8 | 7 | 101.6 | 4 | 7/8 | 125 | 1 | M24 | 3.7 |

| 1 1/4 | 32 | 160 | 28.6 | 63.5 | 7 | 111.1 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 73 | 7 | 123.8 | 4 | 1 | 140 | 1 1/8 | M27 | 5.9 |

| 2 | 50 | 215 | 38.1 | 92.1 | 7 | 165.1 | 8 | 7/8 | 145 | 1 | M24 | 10.1 |

| 2 1/2 | 65 | 245 | 41.3 | 104.8 | 7 | 190.5 | 8 | 1 | 160 | 1 1/8 | M27 | 15.9 |

| 3 | 80 | 265 | 47.7 | 127 | 7 | 203.2 | 8 | 1 1/8 | 180 | 1 1/4 | M30 | 21.8 |

| 4 | 100 | 310 | 54 | 157.2 | 7 | 241.3 | 8 | 1 1/4 | 195 | 1 3/8 | M33 | 33 |

| 5 | 125 | 375 | 73.1 | 185.7 | 7 | 292.1 | 8 | 1 1/2 | 250 | 1 5/8 | M39 | 64 |

| 6 | 150 | 395 | 82.6 | 215.9 | 7 | 317.5 | 12 | 1 3/8 | 260 | 1 1/2 | M36 | 75 |

| 8 | 200 | 485 | 92.1 | 269.9 | 7 | 393.7 | 12 | 1 5/8 | 290 | 1 3/4 | M42 | 136 |

| 10 | 250 | 585 | 108 | 323.8 | 7 | 482.6 | 12 | 1 7/8 | 335 | 2 | M48 | 232 |

| 12 | 300 | 675 | 123.9 | 381 | 7 | 571.5 | 16 | 2 | 375 | 2 1/8 | M52 | 314 |

| 14 | 350 | 750 | 133.4 | 412.8 | 7 | 635 | 16 | 2 1/4 | 405 | 2 3/8 | M56 | 443 |

| 16 | 400 | 825 | 146.1 | 469.9 | 7 | 704.8 | 16 | 2 1/2 | 445 | 2 5/8 | M64 | 591 |

| 18 | 450 | 915 | 162 | 533.4 | 7 | 774.7 | 16 | 2 3/4 | 495 | 2 7/8 | M72 | 795 |

| 20 | 500 | 985 | 177.8 | 584.2 | 7 | 831.8 | 16 | 3 | 540 | 3 1/8 | M76 | 1022 |

| 24 | 600 | 1170 | 203.2 | 692.2 | 7 | 990.6 | 16 | 3 1/2 | 615 | 3 5/8 | M90 | 1648 |

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | RF Dia. | RF Height | PCD | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | ||||||||

| 1/2 | 15 | 135 | 30.2 | 34.9 | 7 | 88.9 | 4 | 3/4 | 120 | 7/8 | M20 | 3.2 |

| 3/4 | 20 | 140 | 31.8 | 42.9 | 7 | 95.2 | 4 | 3/4 | 125 | 7/8 | M20 | 3.7 |

| 1 | 25 | 160 | 35 | 50.8 | 7 | 108 | 4 | 7/8 | 140 | 1 | M24 | 5 |

| 1 1/4 | 32 | 185 | 38.1 | 63.5 | 7 | 130.2 | 4 | 1 | 150 | 1 1/8 | M27 | 7.8 |

| 1 1/2 | 40 | 205 | 44.5 | 73 | 7 | 146 | 4 | 1 1/8 | 170 | 1 1/4 | M30 | 10.5 |

| 2 | 50 | 235 | 50.9 | 92.1 | 7 | 171.4 | 8 | 1 | 180 | 1 1/8 | M27 | 18 |

| 2 1/2 | 65 | 265 | 57.2 | 104.8 | 7 | 196.8 | 8 | 1 1/8 | 195 | 1 1/4 | M30 | 25.5 |

| 3 | 80 | 305 | 66.7 | 127 | 7 | 228.6 | 8 | 1 1/4 | 220 | 1 3/8 | M33 | 39 |

| 4 | 100 | 355 | 76.2 | 157.2 | 7 | 273 | 8 | 1 1/2 | 255 | 1 5/8 | M39 | 61.5 |

| 5 | 125 | 420 | 92.1 | 185.7 | 7 | 323.8 | 8 | 1 3/4 | 300 | 1 7/8 | M45 | 102 |

| 6 | 150 | 485 | 108 | 215.9 | 7 | 368.3 | 8 | 2 | 345 | 2 1/8 | M52 | 157 |

| 8 | 200 | 550 | 127 | 269.9 | 7 | 438.2 | 12 | 2 | 380 | 2 1/8 | M52 | 241 |

| 10 | 250 | 675 | 165.1 | 323.8 | 7 | 539.8 | 12 | 2 1/2 | 490 | 2 5/8 | M64 | 470 |

| 12 | 300 | 760 | 184.2 | 381 | 7 | 619.1 | 12 | 2 3/4 | 540 | 2 7/8 | M72 | 575 |

Disclaimer – Please check with ASME B16.5 before using it.